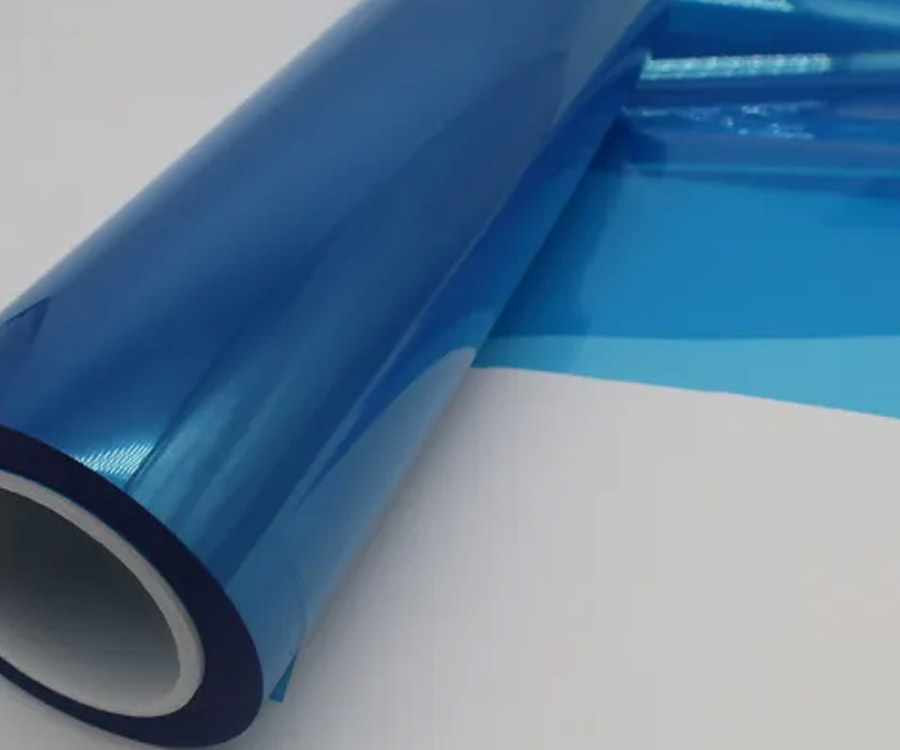

Multilayer & Monolayer Films for Packaging

Spine Poly Tech produces both Multilayer and Monolayer Films to cover the full spectrum of packaging requirements, from cost-effective general-purpose films to high-performance barrier solutions. This allows brand owners and converters to choose the right structure for each application and market segment.

- Multilayer films provide improved barrier, strength, and functionality through co-extrusion.

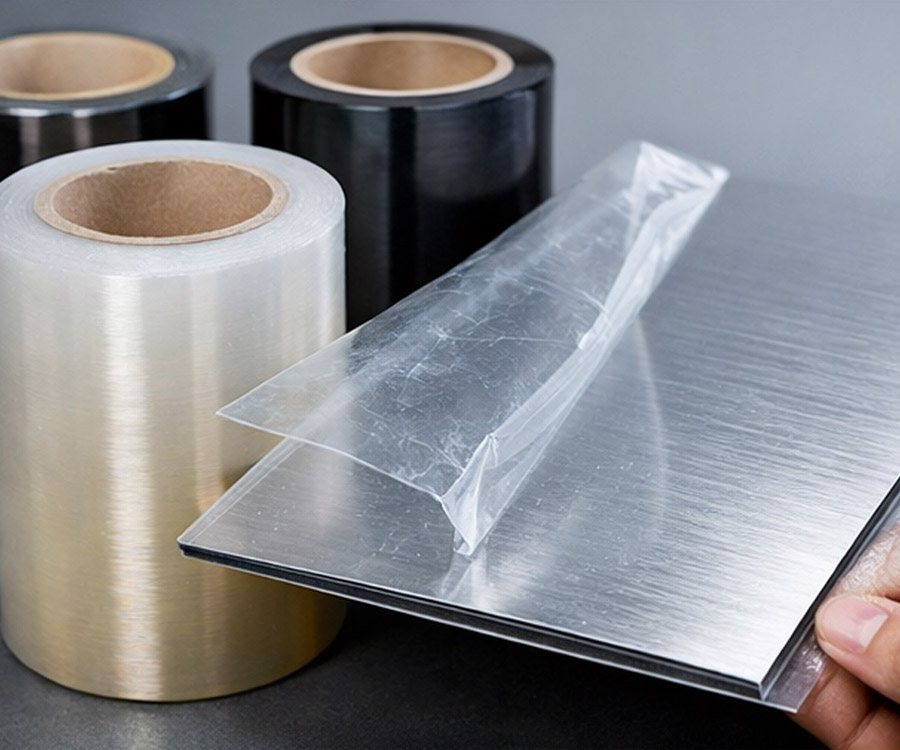

- Monolayer films offer simplicity, easy recyclability, and competitive pricing.

- Wide range of PE-based materials and blends to tune clarity, stiffness, and toughness.

- Available as plain, printed, or lamination base film.

- Suitable for both food and non-food packaging applications.

- Multilayer: 3–5 layer PE structures with optional specialty polymers for barrier and strength.

- Monolayer: LDPE, LLDPE, MDPE, or HDPE films depending on required performance.

- Thickness and width: Standard packaging ranges, customizable based on machinery and pack design.

- Options: Slip/anti-block, UV, antifog, antistatic, coloured or clear, treated or untreated.

- Primary and secondary food packaging: pouches, overwraps, liners, and bags.

- Industrial and agricultural packaging where toughness and cost efficiency are key.

- Lamination webs for multi-material packaging structures.

- Consumer and retail packaging requiring good optics and printability.

Why Choose Spine Poly Tech Multilayer & Monolayer Films

Spine Poly Tech helps customers choose between multilayer and monolayer structures based on shelf-life needs, regulatory requirements, machine constraints, and sustainability goals, rather than pushing a single technology. Consistent film quality and technical support ensure smooth conversion and reliable performance in the field.