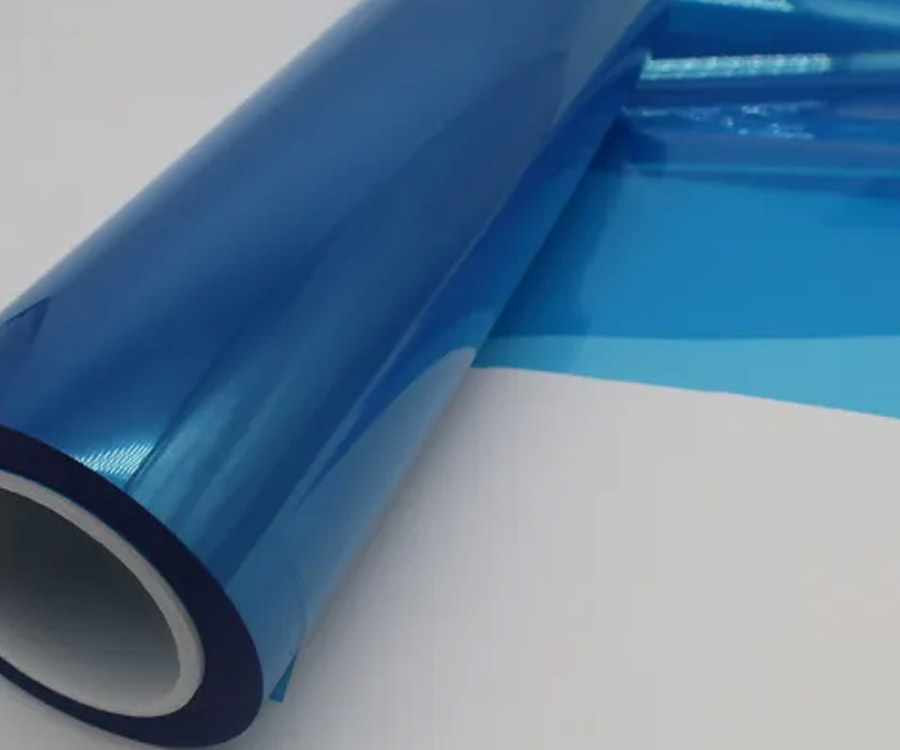

Co-Extruded LDPE Films

Co-Extruded LDPE Films from Spine Poly Tech are high-performance multilayer polyethylene films that combine the strength, clarity, and sealing performance required for demanding packaging and industrial applications. Using advanced co-extrusion technology, multiple layers of LDPE and compatible polymers are fused into a single film to deliver better barrier properties and mechanical strength than standard monolayer films.

- Multilayer structure for enhanced strength, puncture resistance, and downgauging.

- Excellent clarity and gloss for attractive product presentation.

- Strong heat-seal performance on high-speed machines.

- Good moisture barrier for food and industrial products.

- Customizable slip, stiffness, and optical properties as per application.

- Structure: 3 to 5 layer co-extruded LDPE/LLDPE blends (customizable).

- Thickness range: Approx. 20–200 microns (to be finalized with client).

- Width: Up to typical industrial widths suitable for form-fill-seal and liner applications.

- Options: Clear, tinted, or coloured; corona-treated for printing; with or without additives (UV, anti-block, slip).

- Food and FMCG primary and secondary packaging (pouches, liners, overwraps).

- Industrial liners, bags, heavy-duty sacks, and pallet covers.

- E-commerce and retail packaging requiring strength and good optics.

- Lamination base film for multilayer packaging structures.

Why Choose Spine Poly Tech Co-Extruded LDPE Films

Spine Poly Tech combines modern co-extrusion lines with strict quality checks to deliver consistent gauge, high seal integrity, and application-specific performance for every roll. Films are developed in consultation with customers to balance performance, cost, and processing efficiency on their existing packaging machinery.