Manufacturing & Quality

World-Class Manufacturing Backed by Technology and Precision / Hygiene Standard

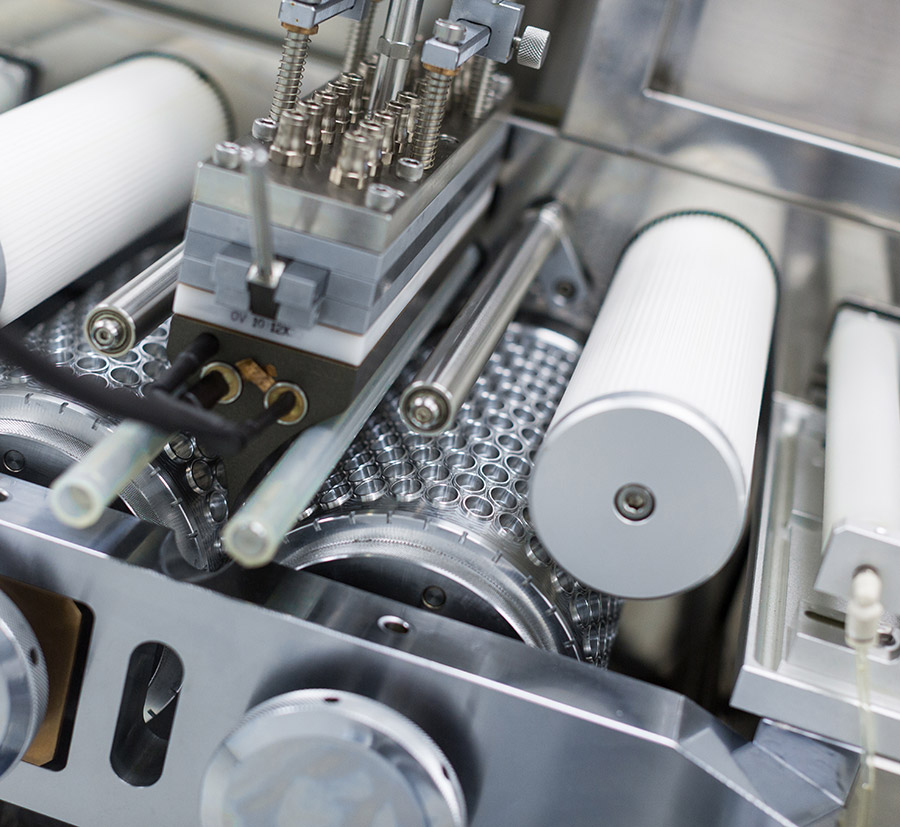

At Spine Polyfilm Industries, innovation meets precision. Our state-of-the-art manufacturing facilities are equipped with advanced multilayer extrusion, co-extrusion, and printing technologies that enable us to produce high-performance polyfilms meeting global quality standards.

Every product rolling out of our plant reflects engineering excellence, consistency, and sustainability, built on decades of expertise in polyethylene and polypropylene film manufacturing.

Manufacturing Infrastructure

Our world-class manufacturing facility in Rajkot, Gujarat, India spans over AREA ? strategically designed for end-to-end polyfilm production from resin compounding to extrusion, printing, lamination, and finishing.

- Multi-layer blown and cast film extrusion lines (3-layer to 7-layer)

- High-speed rotogravure and flexographic printing machines (up to 8 colors)

- In-house slitting, sealing, and cutting units

- Advanced film inspection and defect detection systems

- Controlled environment for hygienic and medical-grade film production

Our facility operates on lean manufacturing principles and adheres to ISO-certified quality management systems, ensuring precision, efficiency, and scalability. Providing hygiene standard, closed loop environment, inset killer, air shower, sanitization, positive pressure in production area and clean room.

Technology & Equipment

We use the latest technology sourced from global leaders in film extrusion and processing.This integration allows us to maintain uniform film thickness, improved optical properties, and enhanced mechanical strength — essential for high-quality flexible packaging.

Our Technological Edge Includes:

- Automatic gravimetric dosing and blending system

- Online thickness & gauge control

- Corona treatment and surface modification units

- Winding & roll-handling systems

- Auto Tension Controlled

- Real-time process monitoring and data tracking

Through automation and precision engineering, Spine Polyfilm Industries achieves repeatable quality and minimal waste, optimizing both performance and sustainability.

Quality Control & Assurance

Quality is the foundation of everything we manufacture.Every stage — from raw material procurement to final product dispatch — undergoes stringent quality testing and validation to ensure compliance with national and international packaging standards.

Quality Control Measures:

- Raw material testing for melt flow index and density

- Optical & mechanical property checks (Haze, Gloss, Tensile, Tear, Dart Impact)

- Heat seal, slip, and friction coefficient analysis

- Barrier property evaluation for moisture and gas permeability

- Continuous in-line inspection and defect detection

Our Quality Assurance (QA) team ensures that each film meets the highest benchmarks of clarity, strength, and performance, maintaining complete traceability and documentation for every batch.

Continuous Improvement & R&D

At Spine Polyfilm Industries, we believe excellence is an ongoing process. Our in-house Research & Development (R&D) team continuously explores new film structures, polymer blends, and process optimizations to improve performance, reduce material consumption, and enhance end-user satisfaction.

Our R&D Focus Areas Include:

- Lightweight and high-barrier packaging films

- Eco-friendly and recyclable material development

- Breathable and medical-grade film technology

By integrating customer feedback and technological advancements, we ensure our films evolve with market needs and sustainability goals.

Sustainability & Environmental Responsibility

Sustainability lies at the core of our manufacturing philosophy.

We are deeply committed to reducing environmental impact and promoting circular economy practices through efficient resource utilization and responsible production.

Sustainability Initiatives:

- 100% recyclable and reusable film manufacturing

- Energy-efficient extrusion

- In-house recycling unit for PIR (Post Industrial Recycling)

- Solar energy utilization for plant operations

- Minimal carbon footprint through optimized logistics

Our commitment goes beyond compliance — we are dedicated to building a greener, cleaner, and more responsible packaging future.